International

Feed ration planning with cereals – what is important?

After the harvest the use of feed supplies and the need of supplementary feedstuff for pig feeding have to be carefully evaluated in order to use the existing resources “cereal harvest” and “stocking rate” effectively. An animal feed calculator can be a sensible planning support.

Cereals are harvested and stored. Now, the use should be planned. What has to be taken into account in regard to this important business decision? A livestock farm with pigs has to analysis which feed is needed for its piglet production or pig fattening and which home-grown feed supplies should be used. The aim is to implement a value added chain of profitability, home-grown crops and sustainability.

Influencing factors are crop on one hand production capacities/conditions and hence resultant harvested yields and qualities (available amount) and on the other hand finishing capacities and aims (how many pigs and which ENERGY and SID-Lys use). A sustainable overall business strategy prefers long crop rotations, which lengthen the classical oilseed rape-wheat-barley crop rotation (Figure 1).

Apart from home-grown feed supplies a complete ration also includes mineral and protein sources like soybean and oilseed rape meal or feed supplements, which are calculated with feed formulation software. The software delivers the most cost-efficient combination/mixture of straight feeds, which fulfil the requirements in regard to feed value and sustainability.

How does crop rotation influences pig production?

In order to CONTROL an overall strategy it makes sense to determine the economic value of certain changes in the feed diet. For example: Is it for the pig production an economical advantage or disadvantage if the crop rotation is lengthened by certain crops?

Because therethrough rather unusual raw materials like rye, maize, oats or grain legumes became available for feeding. And if it was economical sensible what would be the impact of those feed components on the animal and how would the farms’ nutrient flow be influenced?

SU-rye calculator reveals correlations

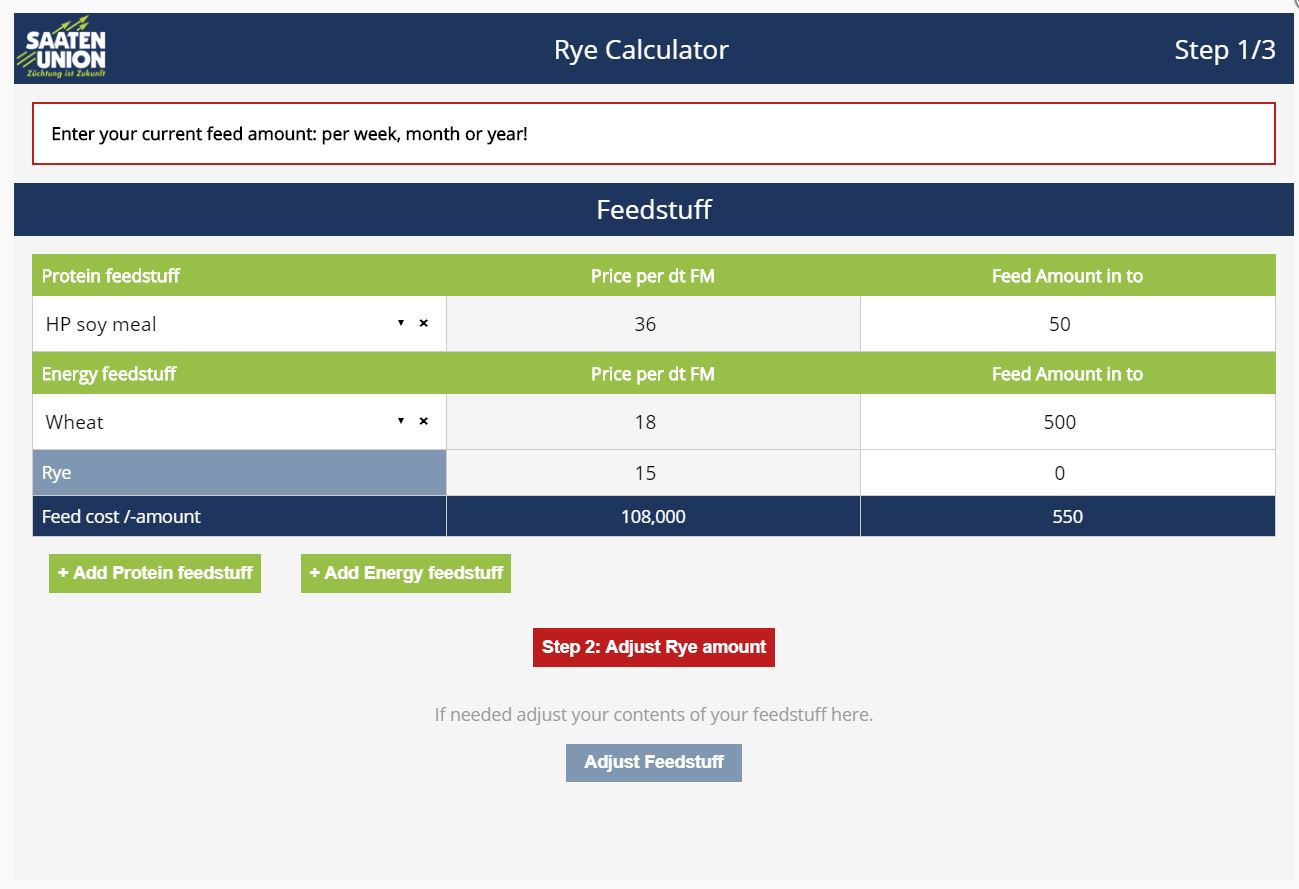

This tool quickly gives a first impression on the impact of changing raw materials in feeding. Users are able to adjust feed values of ENERGY and protein sources so that the quality of home-grown supplies and supplements can be considered. Like that farm specific suggestions for more comprehensive planning and optimising steps in regard to crop cultivation as well as feeding can be given.

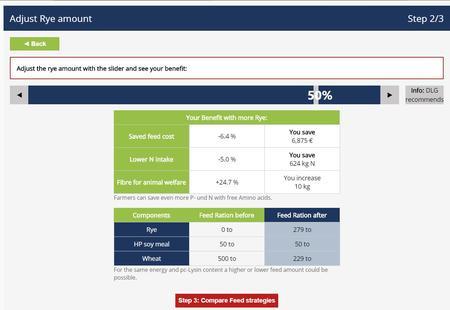

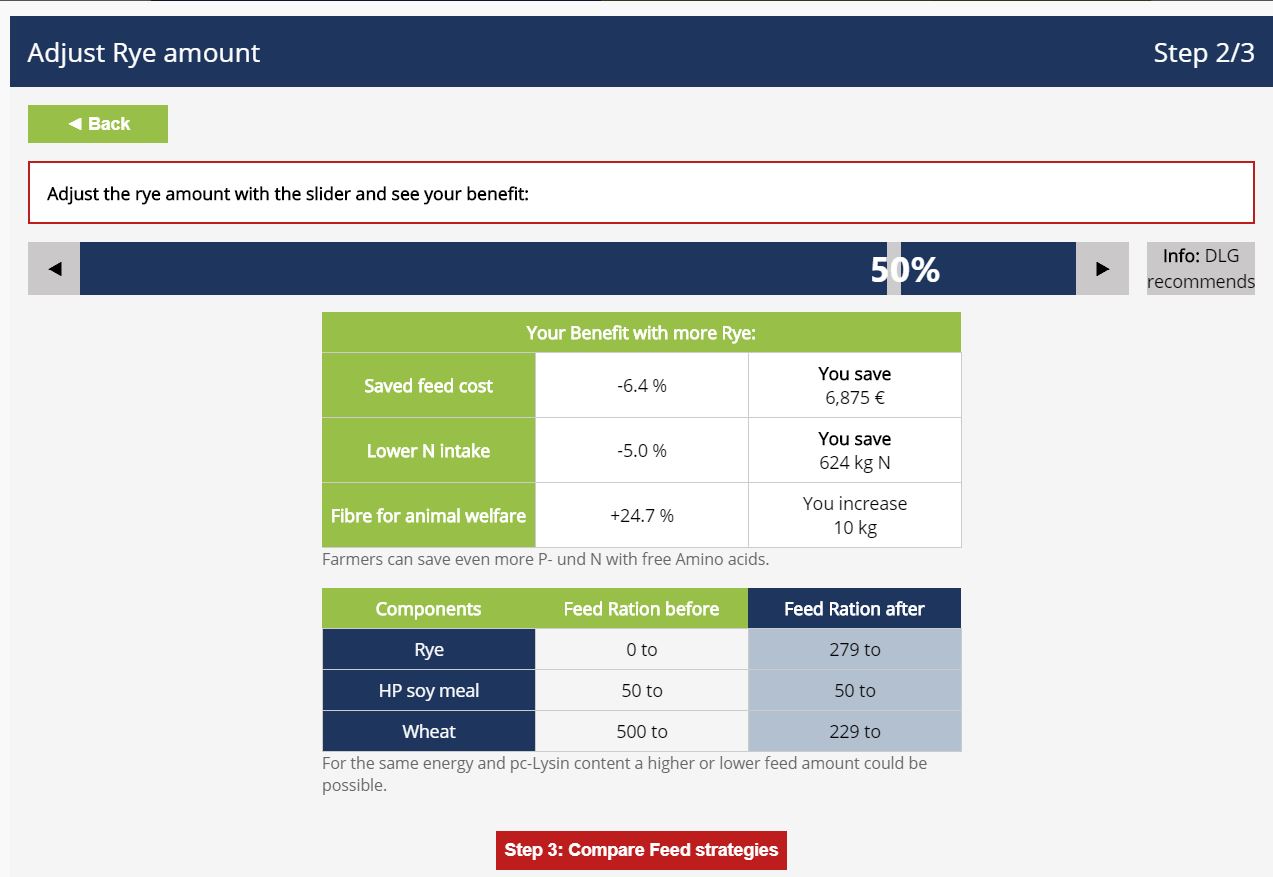

SU-calculator shows how the raw material costs of the main components but also of crude protein and gross protein consumption change if at a given total ENERGY and protein source usage rate (“SO FAR = actual”) ENERGY sources are proportionally exchanged by rye (NEW = “target”). The exchange takes places according to the Löhr-exchange-method. ENERGY sources in the diet are exchanged by rye at a desired level. As rye being a cereal it mainly delivers ENERGY in a diet. It will be assured that the new target diet with rye supplies the same ENERGY and SID-Lys levels as the so far used “actual” diet. Only in other feed value characteristics like crude protein, phosphorus, calcium, NDF, ADF or fibre contents shifts can occur if the component proportion in regard to total usage changes significantly. It is only possible to achieve an equivalent ENERGY and protein level in different component combinations if in the course of calculation the protein source usage rate can be adjusted. As main protein source soybean or oilseed rape meal come into question, which has to be allowed for.

Not taken into account is the use of free amino acids, which are essential for significantly N and P reduced diets. When using other feed value characteristics it is only possible to balance occurring oversupply or undersupply situations if the diet mixture is optimised for specific feeding phases. Like that the performance is not reduced when changing from the actual to the target supply.

Example: 3-year crop rotation versus 4-year crop rotation

The example farm for a three year crop rotation (oilseed rape-winter wheat-winter barley) can use from 100 hectare arable land on average 259 ton of wheat and 243 ton of barley as home-grown supplies for its pig fattening. Prices are calculated with average production costs. However, they can be adjusted if necessary.

|

|

|

In comparison to the three year crop rotation, the four year crop rotation of our example allows an increase of the rye proportion in the main component combination up to 22% (Figure 3). Subsequently, approx. 3,000 € can be saved in feeding costs if based on current prices. Additionally, the pigs’ diet needs 1.8 % less N and 2.1% less P. Increasing the rye proportion with the slider leads to even further cost savings. Of course, the scale of cost savings is strongly influenced by the current market situation of the main components. The maximum limit of the rye proportion in the diet depends on the justifiable ingredient ratio during various feeding phases 1. The recommendations of the German Agricultural Society (DLG) can be taken as orientation values.

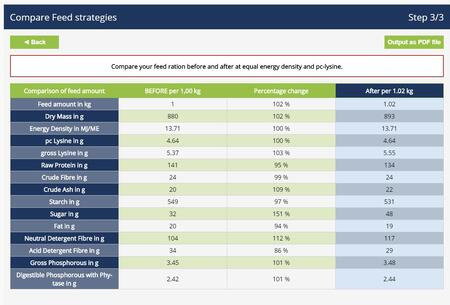

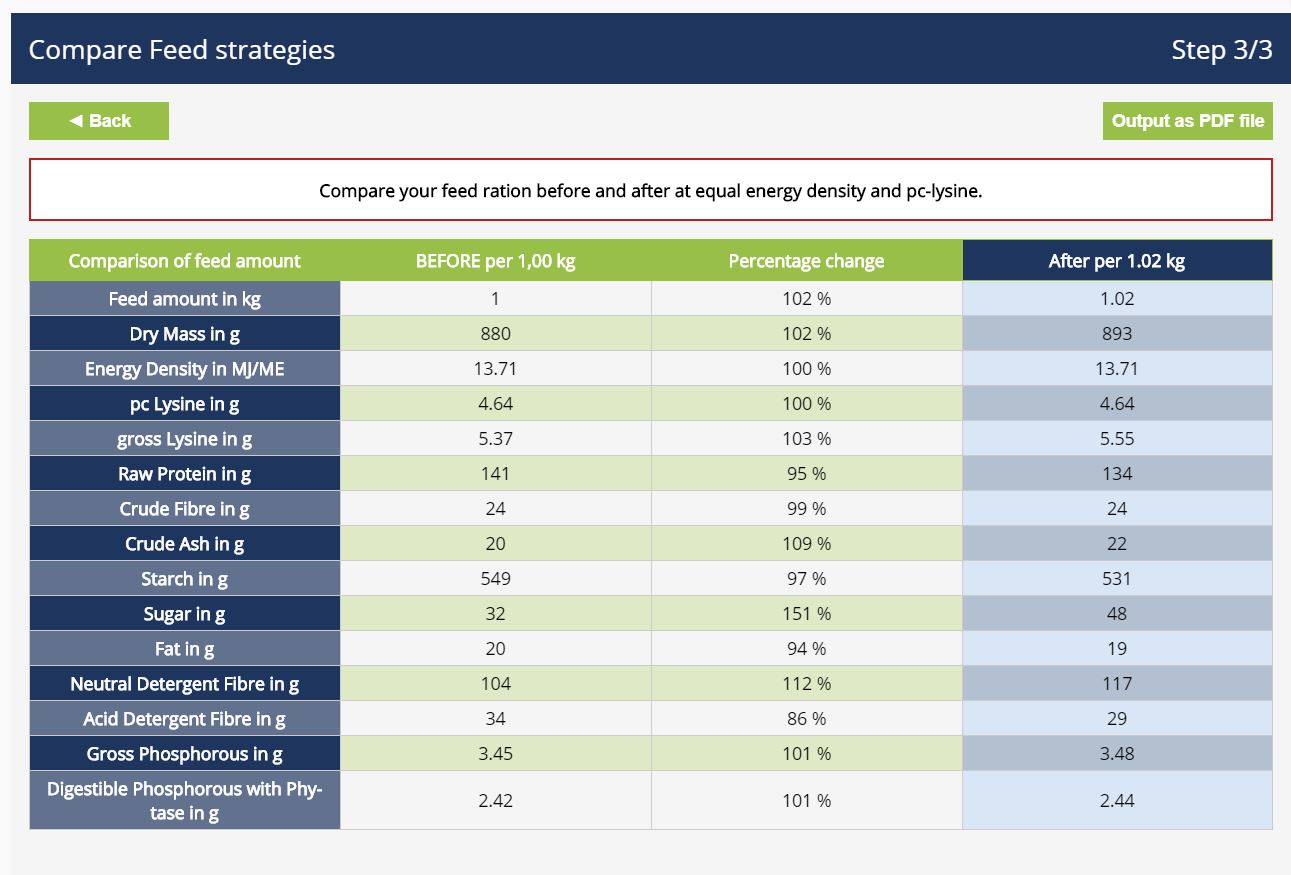

The target-actual comparison for further feed value characteristics in Figure 4 “Comparison of feeding strategies” also indicates the need of adjusting feed supplements. In order to take up the identical amount of ENERGY and SID-Lys levels a bigger or smaller feed ration could be necessary. For fileing or further discussions with the animal feed advisor a pdf can be generated.

Like that approximately:

(602,000 kg main components x 13.27 MJ ME/kg) / 35 MJ/kg growth rate = 228.244 kg

growth can be generated.

In any case, the limiting factor amino acid lysine has to be taken into account. In our three year crop rotation example a supplement of 100 tons of high protein soybean meal supplies on average 13.27 MJ ME/kg of metabolisable ENERGY in the main component combination. This total growth rate corresponds to the fattening of approximately 2,538 finisher pigs of 30 to 120 kg live weight. However, the actual diet mixture of the main components only supplies enough essential amino acid lysine for about 2,341 finisher pigs. Thus, there is still the need for supplementing amino acid. This can only be calculated individually for every fattening phase and summarised for the total fattening with animal feed formulation software. Those calculations should also regard mineral nutrients, trace elements, vitamins and fibres according to the animal requirements.

Summary

SU-calculator is a useful tool to determine initial rough key factors for the main components (ENERGY and protein sources) in pig feeding. Thereby, the main focus is on the change of feed raw material costs and N and P use as well as the supply of dietary fibers for finishing pigs. Those changes take place if in practice common combinations of cereal/protein sources are altered with rye. For the SU-calculator only very few quantity values are needed concerning the actual usage rate of the main components, nutritional values of feedstuff and appropriate raw material valuations. The tool generates new ideas in regard to controlling feedstuff costs and farm nutrient management.

Dr. Wilke Griep